The bearings can be the most important part of the spindle and determine its maximum rpm as well as its rigidity and suitability for CNC.

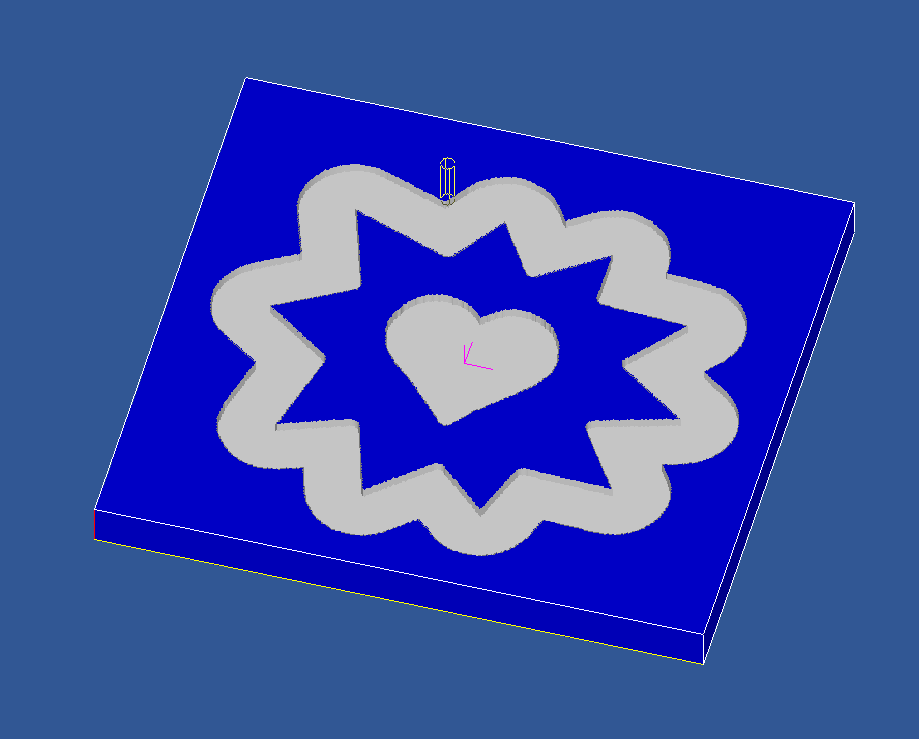

#Cutviewer mill change stock dimensions plus

Angular Contact Bearings: This particular spindle has two angular contact bearings plus two deep groove ball bearings (salmon colored).

Let’s go over the role of each component: Here’s a cutaway of a cartridge spindle set up for ATC (Automatic Tool Changer) so you can get an idea of the components: They’re convenient to swap out and rebuild while keeping the machine going, they’re more convenient to manufacture than fabricated spindles, and they generally just work well. Cartridge SpindlesĬartridge Spindles are what pretty much every modern VMC uses. That’s the sort of construction used in a Bridgeport milling machine or many Chinese Import machines such as the RF-45, for example. Lastly, there are fabricated spindles where the parts such as the spindle bearings are fitted to a (typically) cast iron housing. Self-contained spindles incorporate the rotating assembly and motor all-in-one.

For example, Trim Routers are popular with the DIY CNC crowd, especially for CNC Routers. Then there are self-contained spindles of various kinds. There are cartridge spindles that are just the rotating assembly without motor or transmission. The transmission matches the highest power rpm range of the cnc spindle motor to the spindle rpms that are ideal for the particular speeds and feeds of the material being cut. A cnc spindle motor with optional transmission of some kind rotates the cnc spindle. It consists of a rotating assembly with a taper where tool holders may be installed. The cnc spindle is the heart of any mill.

0 kommentar(er)

0 kommentar(er)